Scales are tools used to judge weight or calculate mass. They are not to be confused with musical scales (minor scale, major scale, chromatic scale, pentatonic scale, etc.). They are also not to be confused with sizing scales like inch scales, price scales, or universal scales. Inch scales mark rulers. Read More…

Load Cell Central is a leading manufacturer of load cells and industrial weighing equipment. We specialize in standard and custom load cells and digital indicators, floor scales and platform scales. Choose from thousands of types and models. We offer load cell repair to help in the reduction of costs.

Top quality industrial weighing equipment for 180 years. Call or click today to find a dependable Fairbanks rep near you. Always setting new standards in scale design, try our Weigh in Motion systems – high speed package scales & slow speed to highway speed robust WIM Scales & PC Mobile Weighing Systems. See the extensive list of ALL our product types, meeting the special needs of each customer.

Walz Scale is a leading global supplier and service support provider of heavy-duty truck & rail scales, volumetric load scanners, dimensional and precision weighing systems for use in transportation, agriculture, chemical, laboratory, aggregate, manufacturing, waste, recycling and mining applications. For over 54 years, Walz Scale has been providing the highest level of weighing products and...

We have made it our goal to treat each and every customer like number one in order to keep them coming back to us for all of their industrial scale needs and also in hopes of turning first time customers into lifelong connections! Our skilled engineers will be able to assist you in find a product that will perfectly fit your needs. For more information on what we may be able to do for you visit...

Since 1929, Brechbuhler Scales has been a leader offering a wide variety of industrial scales such as balance scales, digital scales, truck scales, crane scales, floor scales, platform scales and more. We also provide rental scales from our large inventory and are ANSI 9002 registered.

More Scale Manufacturers

Scales are devices for determining weight or mass. They should not be mistaken for musical scales (such as minor, major, chromatic, pentatonic) or measurement scales like inch scales, price scales, or universal scales. Inch scales are found on rulers, price scales are used in commodity trading graphs, and universal scales are utilized by engineers and architects for measurements.

Applications of Scales

Price scales, inch scales, and universal scales each serve distinct purposes. Price scales, used in retail and finance, display product and service costs, aiding consumer understanding and investor analysis. Inch scales, crucial in construction and engineering, provide precise measurements in inches and fractions. Universal scales, also known as engineer’s scales, measure various units like length, angles, and maps, with multiple graduations for easy unit conversions. Each scale type enhances accuracy and clarity in its respective field.

History of Scales

Scales have been used for thousands of years, with the earliest balance scales found in the Indus River Valley dating back to 2400-1800 BC. These tools helped tradespeople value goods by weighing them against set masses. By 1878 BC, Egyptians were using balance scales to measure gold. In China, balance scales dating to the 3rd or 4th centuries BC were found in a tomb near Changsha, Hunan, alongside bronze weights.

After the Italian Renaissance, balance scales remained the most accurate despite various attempts to innovate. During this period, Galileo’s friend, Santorio Santorio, invented the first successful non-balance scale: a weighing chair placed on a balance platform. In the late 17th century, tradespeople began using standardized weights for greater accuracy and transparency, leading to new scale designs. Among these was the Roberval balance, invented in 1699 by Gilles Personne de Roberval, which provided accurate measurements regardless of weight placement in the pans.

In 1770, Richard Salter invented spring scales using a spring to measure load tension, a design still used in post offices today. In 1843, Sir Charles Wheatstone improved Samuel Hunter Christie’s electrical circuit to measure resistance, creating the Wheatstone bridge circuit. This innovation became the basis for load cells, key components of digital scales.

Wheatstone perfected the circuit in 1843, but it wasn’t effectively used until 1943 when engineers began mass-producing bonded strain gauges for load cells. Nearly forty years later, Richard Loshbough and Edward Pryor patented the first American digital scale. Advancements continue, such as the hybrid scale with flexible arms introduced four years ago, which prevents tipping when weighing heavy loads on edges. Industrial scale manufacturers are constantly improving measurement products, aiming for greater accuracy and versatility in the future.

Industrial Scale Design

When designing or selecting an industrial scale, suppliers must consider factors such as the intended environment, types of materials to be weighed, weight range, and required precision. While suppliers typically offer a range of standard scale designs, they can also customize scales to meet specific customer needs. For example, they can create scales with capacities from a few grams to over 80,000 pounds, suitable for weighing everything from truckloads to laboratory gases.

Precision is vital, especially for larger scales, which may round off to the nearest half pound or ton. Conversely, smaller scales can measure accurately down to the milligram. Therefore, it is crucial to communicate the level of accuracy required for your application.

Features of Industrial Scales

Scales incorporate various features and components to accurately measure weights and provide reliable results. Springs are often found in mechanical scales and function by expanding or contracting based on the applied weight, allowing the scale to display the corresponding measurement.

Load cells, on the other hand, are commonly used in digital scales and electronic weighing systems. These transducers convert the force of the load into electrical signals, which are then processed to determine the weight accurately. Hydraulic components can be found in heavy-duty industrial scales and hydraulic load cells, which use pressurized fluid to measure weight with high precision.

Balance components, including levers and pivots, are essential in mechanical balance scales, where they provide the counterbalancing required for accurate weight measurement. Additionally, modern scales often come equipped with features such as digital displays, calibration mechanisms, and taring functionality. Digital displays show the weight measurement in an easy-to-read format, while calibration mechanisms enable calibration for accuracy. Taring allows the scale to reset to zero when containers or objects are placed on it, allowing for the measurement of the contents only.

These features collectively enhance the efficiency and reliability of scales across various applications, making them indispensable tools in numerous industries and everyday use.

Types of Industrial Scales

Industrial scales serve a multitude of applications, providing precise measurements across diverse industries. One way to categorize these scales is by the weighing mechanism or technique they employ. Among the most common types are hanging scales, crane scales, platform scales, and balance scales.

Hanging scales, often referred to as hang scales, range in size from compact luggage scales to larger crane scales. These scales operate as a type of spring scale, where the load is suspended from a hook or chain, and sensors positioned above the load measure the weight. Their versatility makes them suitable for various settings, including travel and fishing.

Crane scales, a subset of hanging scales, often utilize hydraulic power in addition to or instead of a spring mechanism. While they share similarities with traditional hanging scales, crane scales are typically more robust and capable of handling heavier loads. These scales can also be used in smaller forms for specific applications, such as weighing luggage or fish, where the hanging feature might be less emphasized.

Platform scales are designed with a scale pan or surface on which items are placed for weighing. Underneath this surface, an intricate system of springs, load cells, or levers is arranged to determine the weight of the items. Some platform scales, like bench scales and floor scales, feature a single surface, while others are equipped with multiple platforms for diverse applications.

Balance scales, commonly known as “balances,” measure mass and are a specific type of platform scale. Traditionally, they operate using two weighted pans and a beam or a pivoted horizontal lever with equal-length arms, suspending the pans on either side. To ascertain the mass, a technician places the item in one pan and known standard weights in the other until the beam achieves equilibrium. Variations of the traditional balance scale include microbalances, pendulum balance scales, analytical balances, electronic analytical balances, and Roberval balances.

Customers can select from a wide range of scales, including bench scales, counting scales, digital scales, electronic scales, portable scales, medical scales, pet scales, and kitchen scales.

Bench scales are compact and easy to handle, designed for placement on a table, counter, or bench. These versatile scales are commonly employed in pharmacies for weighing pills or in grocery stores for measuring produce, ensuring precise and convenient usage in various environments.

Counting scales are tailored for accurately counting coins, currency, or specific items. They employ a sophisticated memory system that retains the weight information of individual objects, such as nickels or quarters, enabling precise counting and recording of the total number of items weighed, which is crucial for effective inventory control.

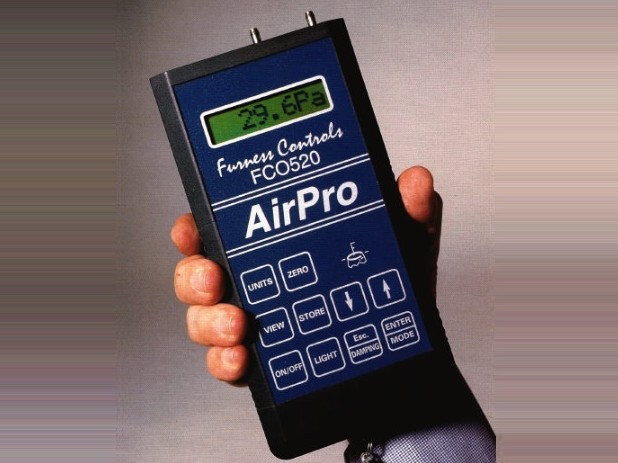

Digital scales provide a straightforward user experience by displaying load weights on a digital screen. This clear digital readout allows for quick and accurate readings, making them superior to traditional analog scales in terms of convenience and precision.

Electronic scales, also known as electronic weigh scales, function by utilizing electrical signals, currents, and charges. These scales incorporate an electric motor to determine loads, offering high accuracy and dependability. Virtually any scale can integrate electronic technology, making them suitable for a broad range of applications.

Portable, medical, pet, and kitchen scales are each designed for specific uses, catering to diverse user requirements. Portable scales offer the convenience of easy transport for measurements on the go, while medical scales provide the precision needed in healthcare settings. Pet scales are designed for veterinary use, and kitchen scales offer culinary accuracy for measuring ingredients.

Accessories for Scales

Enhancing scale functionality in various settings involves key accessories. Remote indicators display weight from a distance, ideal for industrial use. Tables and stands ensure accuracy with stable platforms. Cables connect devices for data transfer. Power adaptors provide consistent power, avoiding battery dependence. Printers enable receipt, label, or report printing for commercial use. Barcode scanners aid in quick item identification and tracking. Foundations stabilize large scales, preventing vibrations and ensuring precision.

To determine necessary scale accessories, assess its intended use and application requirements. Identify the scale’s purpose—commercial, industrial, laboratory, or personal. Consider required measurement accuracy, especially in high-precision settings like laboratories. Evaluate environmental conditions; industrial settings may need stable tables or stands. Adhere to industry regulations, such as printers for retail compliance. Use accessories like barcode scanners and remote indicators to enhance efficiency. Finally, prioritize essential accessories within the budget to ensure improved accuracy and efficiency.

Proper Care for Industrial Scales

Proper care ensures the longevity and accuracy of scales. Clean regularly with a soft, damp cloth, avoiding harsh chemicals. Perform frequent calibration checks and adhere to manufacturer guidelines or seek professional services. Avoid overloading and handle gently to maintain precision. Place on a level surface and protect from moisture. Store in a clean, dry environment away from sunlight and extreme temperatures. Regular maintenance and inspections by qualified technicians help sustain consistent and precise measurements.

Standards for Industrial Scales

In the United States, the National Institute of Standards and Technology (NIST) sets standards for scales and measuring devices to ensure accuracy and fairness in commerce and industry. As a federal agency under the U.S. Department of Commerce, NIST’s standards protect consumers, promote fair trade, and ensure reliable measurements. Adherence to these standards is crucial in industries like pharmaceuticals, research, and manufacturing, guaranteeing product quality and safety. These standards foster trust and integrity in measurements, benefiting both consumers and businesses.

How to Choose the Right Manufacturer

Finding reliable weighing products begins with partnering with an experienced industrial scale manufacturer. With so many options online, it can be challenging to identify the best manufacturers. To help with your search, we’ve curated a list of trusted scale suppliers, including their profiles and contact details, on this page. Start by reviewing the listed suppliers and choose three or four that meet your criteria. Contact each one for a discussion and assess their offerings. Compare their advantages and disadvantages to determine which one best suits your needs.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services