A platform scale is a weighing instrument made of one or two metal plates with a smooth or diamond-shaped surface to hold the objects to be weighed. Platform scales are named because the object being weighed is put on a platform. They are capable of weighing items of 500 to 1000 pounds (226.8 to 453.6 kg). Usually, a ramp is required to lift the object onto the tool. Platform scales are frequently transportable since they are lighter and easier to move than the goods used to weigh. The scale on the left has handles that make it easy to move around.Read More…

Our industrial scales will astound you with their high performance, and longevity! For over six decades we have been providing our customers with exceptional service and products in order to better serve a global market. Our products serve in many different markets including aerospace, automotive and marine as well as many others. Get in touch with us today to learn more about what we can do for...

Load Cell Central is a leading manufacturer of load cells and industrial weighing equipment. We specialize in standard and custom load cells and digital indicators, floor scales and platform scales. Choose from thousands of types and models. We offer load cell repair to help in the reduction of costs.

As a scale manufacturer, OHAUS is a worldwide leader in the production of industrial scales and balance scales. Our line of industrial scales includes electronic scales, bench scales and counting scales. Our mass measurement tools are helpful in the education of students for concepts in math & science. Contact us soon and we will deliver to you reliable results.

Mettler-Toledo’s industrial weighing solutions include accurate, robust WIM systems for high-volume, in-motion vehicle weighing. These systems offer proven reliability & ease of use for vehicle weight enforcement applications – more efficient & cost-effective than static axle or full-platform scales. Our broad range of industrial, food, retail, & lab scales & analytics serves so many...

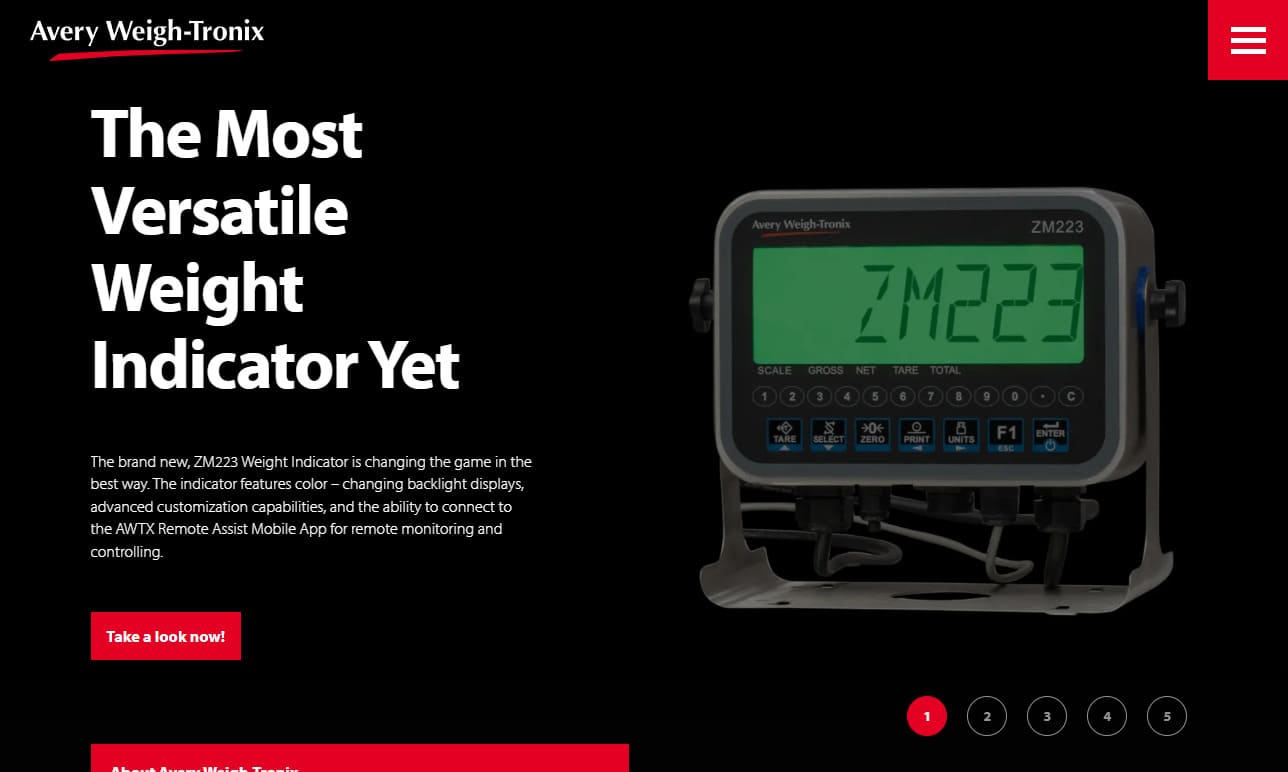

Avery Weigh-Tronix, one of the world’s largest suppliers of weighing solutions, has developed equipment for the full spectrum of industrial scale uses such as counting scales, bench scales, check-weighing scales, baggage scales, cargo scales, lift truck scales and many more. Innovative global weighing solutions – that’s what Avery Weigh-Tronix is all about! ISO 9001 Certified.

If you seek a digital scale, you are looking at the right company. Our selection from many name-brand scale manufacturers includes bench and floor scales; counting scales; electronic scales; freight and shipping scales; grain scales; hanging scales; industrial scales; pallet scales; postal scales. We have digital scales for any weighing application, and will match the price of any competitor for...

At Brecknell Scales, we are dedicated to delivering weighing solutions that combine accuracy, reliability, and ease of use. Our scales are designed to serve a wide range of industries, from manufacturing and logistics to food service and healthcare, ensuring that our customers can rely on precise measurements in their daily operations.

Cardinal/DETECTO is an ISO 9001:2008 registered company who designs, manufactures and markets weighing systems, load cells, weight indicators, remote displays, vehicle weight recording systems, and scales for all industries, including truck scales, weigh-in-motion highway scales, railroad scales, tank/hopper scales, livestock scales, bench scales, floor scales, counting scales, medical scales,...

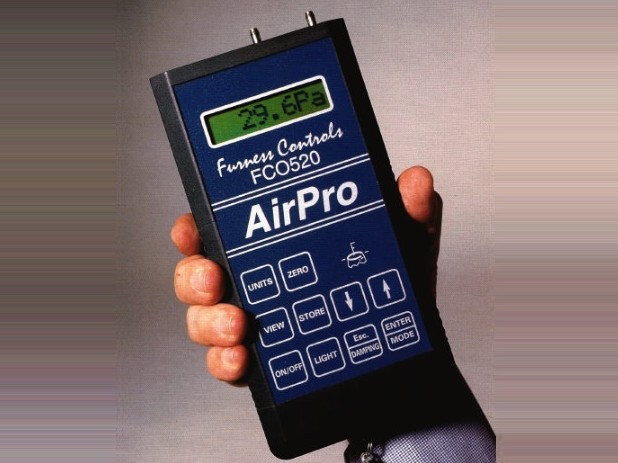

As a leading scale manufacturer, Setra Systems also designs and produces pressure and acceleration sensing equipment. Some industrial scale products include counting scales and laboratory balance scales. We also offer additional accessories like draftshields and dustcovers.

More Platform Scale Manufacturers

Platform and floor scales share similarities in their robust construction and versatile usage, but floor scales are specifically designed to accommodate much heavier goods and higher-capacity weighing needs. Typically, floor scales offer a weight range from 1,000 to 30,000 pounds (453.6 to 13,607.7 kg), making them ideal for industrial environments where large pallets, bulk materials, or oversized containers require accurate weight measurement. In contrast, platform scales—while also engineered for durability and strength—are often found in both industrial and commercial sectors because of their adaptability, reliability, and ability to precisely weigh both large items and multiple small components such as screws, bolts, mechanical elements, and packaged goods. The construction of both types of scales is focused on durability, featuring heavy-duty steel platforms and reinforced load-bearing structures to ensure longevity and consistent performance under rigorous operational demands.

Both platform scales and floor scales play vital roles in manufacturing, logistics, warehousing, shipping, inventory management, and quality assurance. Their precision and reliability help businesses maintain operational efficiency, comply with industry standards, and reduce errors associated with manual weighing. As organizations seek to streamline their weighing processes, selecting the right scale type and model becomes a critical decision factor in achieving accuracy, productivity, and regulatory compliance. Whether you are measuring items for freight calculation, batching raw materials in a production line, or ensuring compliance with legal-for-trade requirements, the right weighing solution is essential to business success.

Types of Platform Scales

Understanding the different types of platform scales can help you make an informed decision based on your unique industry requirements, weighing applications, and environmental conditions. Platform scales are available in a range of configurations, including electronic (digital) and mechanical (analog) models, each offering specific advantages for distinct use cases. By exploring these types, businesses can better align their weighing solutions with operational goals, regulatory needs, and budget constraints. In addition to the traditional categories, platform scales may also be categorized by design, such as low-profile platform scales, portable platform scales, and washdown platform scales, each suited to specialized environments and operational workflows.

Electronic Platform Scales

Electronic platform scales, often referred to as digital platform scales, have become the industry standard in modern weighing technology. Utilizing advanced load cell sensors and microprocessor-based electronics, these scales provide highly accurate and reliable weight measurements. The weight of objects placed on the platform is automatically detected and displayed numerically, typically on a clear, backlit digital readout. This ensures rapid, user-friendly operation and minimizes human error associated with manual or analog readings. When evaluating digital weighing solutions, accuracy, repeatability, and ease-of-use are key decision-making factors for businesses operating in high-volume or regulated environments.

Central to the function of electronic platform scales is the load cell—a precision sensor that converts the mechanical force of an object’s weight into an electrical signal. This signal is then processed by an analog-to-digital converter, resulting in a precise digital output. Many electronic platform scales offer additional features such as programmable tare, unit conversion, piece counting, data logging, and connectivity options such as USB, RS-232, or wireless networking, allowing integration with inventory management systems and process control software. The availability of software integration and remote monitoring enables real-time weight data analysis, automated reporting, and seamless workflow automation—key elements for Industry 4.0 and smart factory initiatives.

These digital platform scales are essential in industries where precision, efficiency, and traceability are paramount—such as food processing, chemical manufacturing, pharmaceuticals, logistics, and shipping. Digital scales also facilitate compliance with standards such as ISO 9001, HACCP, and GMP by providing audit-ready data and consistent measurement accuracy. Compared to analog models, electronic platform scales often feature enhanced durability, automated calibration, overload protection, and the ability to store and transmit weight data for further analysis. Additional benefits include programmable checkweighing functions, accumulation for batch weighing, and customizable alarm thresholds to support process control and quality assurance protocols.

Key advantages of electronic platform scales include:

- High weighing accuracy and resolution, with minimal drift and repeatable measurements over time.

- Intuitive digital displays that eliminate guesswork and reduce training time for operators.

- Advanced features like checkweighing, accumulation, and programmable alarms for quality control.

- Low maintenance requirements and robust construction, suitable for harsh industrial environments.

- Compliance with legal-for-trade certifications, making them suitable for commercial transactions.

- Seamless integration into automated production lines and warehouse management systems (WMS).

- Support for data export and remote diagnostics, optimizing maintenance schedules.

Mechanical Platform Scales

Mechanical platform scales, often referred to as analog platform scales, rely on time-proven mechanical components rather than digital electronics. These scales utilize fundamental principles such as levers, springs, and counterweights to measure weight. Two major types of mechanical platform scales are steelyard scales and spring scales. The steelyard scale operates as a lever, balancing the object’s weight against known counterweights or by reading the displacement on a calibrated beam. The spring balance variant measures force based on the extension or compression of a high-quality spring, with the resulting displacement corresponding to the object’s mass. Traditional beam scales are also commonly used in laboratory and medical settings where mechanical reliability is prioritized.

Unlike digital scales, mechanical platform scales do not require electricity or batteries, making them especially valuable in remote locations, field operations, or facilities where power reliability is a concern. While mechanical scales are celebrated for their durability and resistance to harsh environments, they may offer less precision than their electronic counterparts, especially after extended use or in applications demanding ultra-high accuracy. Analog readouts can be more difficult to interpret, and mechanical components may be susceptible to wear and tear over time, impacting measurement reliability. However, their simplicity of design makes them easier to repair and maintain in environments with limited access to technical support or replacement parts.

Mechanical platform scales are often chosen for applications where simplicity, ruggedness, and low operational costs are prioritized over advanced features or digital connectivity. Examples include agricultural weighing, construction sites, and environments with exposure to dust, moisture, or temperature extremes. These scales are also favored for their minimal maintenance requirements and the ability to operate continuously, even in the absence of a stable power supply. For businesses seeking a cost-effective solution for basic weighing requirements, mechanical platform scales deliver reliable results without the complexity of modern electronics.

Key benefits and considerations for mechanical platform scales include:

- Exceptional durability and long lifespan, even in challenging working conditions.

- No dependency on external power sources, batteries, or electronics.

- Simplicity of operation and low cost, making them accessible for small businesses and rural operations.

- Potential limitations in precision and fewer features compared to digital models.

- Ease of in-field repairs and calibration, particularly important for remote or mobile weighing applications.

Specialized Platform Scale Types

Beyond the core digital and mechanical categories, buyers can choose from a range of specialized platform scale designs tailored to unique operational needs. For instance, low-profile platform scales are ideal for applications where items are rolled or lifted onto the platform, minimizing lifting effort and reducing worker fatigue. Portable platform scales are designed for mobile weighing tasks, offering lightweight construction and integrated wheels or handles. Washdown platform scales feature stainless steel construction and sealed load cells, making them perfect for food processing, pharmaceutical, or laboratory environments requiring frequent cleaning and sanitation.

Other specialty options include explosion-proof platform scales for hazardous environments, pit-mounted platform scales for flush-floor installation, and animal platform scales with non-slip surfaces and animal-friendly features. Understanding these specialized variants allows buyers to select the optimal weighing solution for safety, hygiene, and workflow efficiency.

Applications of Platform Scales

Platform scales are indispensable across a wide spectrum of industries, supporting critical weighing applications that ensure smooth operations, regulatory compliance, and process optimization. Their versatility, strength, and precision make them a preferred choice for many business sectors. Here are some of the most common and high-value use cases for platform scales:

- Industrial and Manufacturing: Weighing raw materials, finished goods, drums, barrels, and large mechanical assemblies to ensure accurate inventory control, quality assurance, and compliance with production specifications.

- Logistics and Warehousing: Managing inbound and outbound shipments, verifying packing lists, and optimizing freight and shipping costs by validating weights for large packages, pallets, and containers.

- Retail and Commercial Operations: Accurately weighing bulk products, food items, or merchandise in grocery stores, supermarkets, and wholesale distribution centers for pricing and inventory management.

- Agriculture and Food Processing: Measuring grain sacks, livestock feed, produce, and processed foods for fair trade, packaging, and regulatory reporting.

- Healthcare and Veterinary: Weighing patients in wheelchairs, hospital beds, or large animals in veterinary clinics and zoos where comfort and safety are priorities.

- Transportation and Aviation: Verifying luggage, cargo, and freight at airports, rail terminals, and shipping docks to ensure compliance with weight restrictions and prevent overloading.

- Recycling and Waste Management: Accurately quantifying recyclable materials, scrap metal, and waste loads for environmental reporting and billing.

- Construction and Materials Handling: Weighing construction materials, aggregates, and supplies on job sites to monitor usage, reduce waste, and optimize logistics.

- Laboratory and Research: Supporting precise measurements for research and development, chemical mixing, and quality control assays where even minor deviations in weight can impact results.

- Automotive and Aerospace: Weighing vehicle components, assemblies, and raw materials to ensure safety, compliance, and process standardization in production and maintenance environments.

By integrating platform scales into these workflows, organizations can gain real-time visibility into material movement, improve safety by avoiding overloading, and automate record-keeping for audits and traceability. The accurate data provided by modern weighing systems supports inventory optimization, cost control, and improved supply chain efficiency. In sectors such as food and pharmaceuticals, platform scales are essential for maintaining traceability and batch integrity, supporting product recalls, and ensuring consumer safety.

Benefits of Platform Scales

Choosing the right platform scale delivers a broad range of operational, financial, and compliance benefits. Here are some key advantages to consider when evaluating platform scales for your business or facility:

- Versatility: Platform scales serve diverse industries and are suitable for weighing small packages, large machinery, containers, and even live animals. Their flexible design enables use in virtually any application, from warehouses and factories to hospitals and farms.

- High Capacity and Durability: The flat, reinforced platform construction supports substantial loads, ensuring reliable performance with both lightweight and heavy-duty weighing tasks. Many models feature corrosion-resistant finishes and sealed components for enhanced longevity.

- Precision and Efficiency: Instantaneous digital or mechanical readouts enable fast, accurate measurements, minimizing delays and helping operators meet deadlines. This translates to higher productivity, reduced labor costs, and fewer errors in billing or inventory records.

- Easy Integration and Automation: Modern electronic platform scales offer connectivity options for integration with ERP, MES, and WMS software, supporting automated data capture, process control, and remote monitoring.

- Compliance and Traceability: Platform scales help companies meet regulatory requirements for labeling, reporting, and quality management, especially in regulated sectors like food, pharmaceuticals, and logistics.

- Cost Savings: By reducing manual handling, minimizing waste, and preventing costly shipping or overloading errors, platform scales contribute to overall cost efficiency.

- Low Maintenance: Both digital and mechanical platform scales are engineered for minimal upkeep, with many models offering self-diagnostic capabilities and rugged parts designed for demanding environments.

- Improved Worker Safety: By providing accurate load information, platform scales help prevent injuries related to overloading, improper lifting, or equipment failure on the shop floor.

- Enhanced Customer Satisfaction: In retail and shipping environments, accurate weighing ensures fair pricing, customer trust, and adherence to trade regulations.

Whether you need to weigh large shipments, track production output, or monitor inventory, platform scales can be tailored to your specific operational requirements. This adaptability, combined with high accuracy and ease of use, makes them a wise investment for organizations seeking to optimize their weighing processes. Advanced models with connectivity and automation features can further drive digital transformation and operational excellence across your business.

How to Choose the Right Platform Scale for Your Needs

When selecting a platform scale, buyers should consider multiple factors to ensure the chosen model aligns with their operational requirements, compliance needs, and budget. Below are key decision criteria to guide your selection process:

- Weight Capacity and Platform Size: Assess the maximum load you need to weigh and ensure the platform size accommodates your typical items—whether small packages or large pallets.

- Accuracy and Readability: Determine the required precision for your application and choose a scale with a suitable resolution and display type. Digital scales typically offer higher accuracy and easier-to-read displays.

- Environment and Durability: Consider whether the scale will be used indoors or outdoors, and if it must withstand exposure to moisture, dust, chemicals, or extreme temperatures. Look for models with appropriate ingress protection (IP) ratings and corrosion-resistant materials.

- Power Source: Decide if you need a battery-operated, mains-powered, or mechanical (power-free) scale based on your location and operational needs.

- Additional Features: Evaluate whether features such as tare, piece counting, data connectivity, overload protection, or wireless operation are beneficial for your workflow.

- Legal-for-Trade Certification: For commercial transactions, select a scale certified as legal-for-trade to ensure compliance with local regulations and fair trading practices.

- Ease of Calibration and Maintenance: Review calibration procedures and service requirements to minimize downtime and ensure long-term reliability.

- Budget and Total Cost of Ownership: Factor in not just the purchase price but also installation, training, maintenance, and potential upgrades over the scale’s lifecycle.

- Software Integration: If you require real-time data transfer to inventory, ERP, or quality control systems, prioritize scales with compatible software and communication interfaces.

- Customization and Accessories: Consider whether you need custom platform sizes, ramps for loading, printer integration, or specialized coatings for hygiene or chemical resistance.

By carefully evaluating these criteria, you can select a platform scale that not only meets your current needs but can also adapt to future operational changes or expansion. Consulting with platform scale manufacturers and suppliers can provide valuable insight into the most suitable models and configurations for your unique application. Don't hesitate to request product demonstrations, application-specific recommendations, or technical datasheets to ensure the selected scale fits seamlessly into your workflow.

Frequently Asked Questions About Platform Scales

What industries use platform scales?

Platform scales are widely used in manufacturing, warehousing, logistics, food processing, agriculture, retail, healthcare, veterinary, transportation, construction, recycling, and waste management. Their adaptability makes them a foundational tool for any operation that requires accurate, high-capacity weighing. Whether you manage a factory, a packaging facility, or a distribution hub, platform scales are essential for process control, inventory management, and quality assurance.

How do electronic platform scales improve productivity?

Electronic platform scales provide immediate, accurate readings and can automate data recording, reducing manual effort and the risk of errors. Integration with inventory or production management systems streamlines workflows, improves traceability, and accelerates order fulfillment. In fast-paced environments, digital scales help operators work efficiently, minimize downtime, and maintain consistent output quality.

Are platform scales suitable for outdoor use?

Yes, many platform scales are designed with weather-resistant materials and sealed components, making them suitable for outdoor and industrial environments. When selecting a scale for outdoor use, prioritize models with high IP ratings and corrosion-resistant finishes. Proper installation and regular maintenance further extend service life in demanding settings.

Can platform scales be customized?

Absolutely. Manufacturers offer a range of customization options, including platform dimensions, weight capacity, specialized coatings, and integration with peripheral devices such as barcode scanners, printers, and remote displays. Customization ensures optimal performance for specific applications. For example, food industry scales may be equipped with washdown capabilities, while logistics operations may require high-capacity scales with integrated RFID readers for automated tracking.

What maintenance is required for platform scales?

Regular maintenance includes periodic calibration, cleaning, inspection for mechanical wear or electronic faults, and ensuring the scale is level and free from obstructions. Following manufacturer recommendations and scheduling professional servicing as needed will maximize the scale’s lifespan and performance. Modern digital models may offer self-diagnostic features, prompting proactive maintenance to prevent unexpected downtime.

How do I ensure my platform scale remains accurate over time?

To maintain accuracy, it's crucial to calibrate your platform scale regularly using certified weights and follow the calibration procedures outlined by the manufacturer. For legal-for-trade applications, periodic verification by authorized service providers may be required. Keeping the platform clean, level, and free from debris also helps prevent measurement errors.

What are the most common mistakes when choosing a platform scale?

Common mistakes include underestimating required weight capacity, overlooking environmental challenges (such as moisture or chemicals), failing to account for integration with existing software, and neglecting the importance of regular calibration and maintenance. Consulting with knowledgeable suppliers and clearly defining your operational requirements can help you avoid these pitfalls.

Choosing the Proper Platform Scale Supplier

To make sure you have the most productive outcome when purchasing platform scales from a platform scale supplier, it is important to compare 4 to 5 suppliers using our list of platform scale companies. Each platform scale supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each platform scale company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple platform scale companies with the same message. When evaluating suppliers, consider their industry reputation, breadth of product offerings, technical support capabilities, and responsiveness to your unique requirements. Look for suppliers who can provide references, timely quotations, and after-sales support—including calibration, repair, and training services. This thorough approach ensures you receive the highest value and support throughout the purchasing and implementation process.

Conclusion: Maximizing Value with Platform Scales

Platform scales are a cornerstone of accurate, efficient, and reliable weighing across countless industries. Their ability to handle a wide range of loads, from lightweight packages to massive industrial components, ensures they remain indispensable for businesses focused on productivity, safety, and regulatory compliance. With options ranging from advanced digital models with integrated software to rugged mechanical units suited for challenging environments, there is a platform scale to fit every operational need.

By understanding the types, applications, features, and benefits of platform scales—and by carefully evaluating suppliers—you can make a confident purchasing decision that delivers long-term value, supports your business goals, and adapts to evolving requirements. Whether you are upgrading an existing weighing system or implementing new solutions in response to business growth, investing in the right platform scale is a strategic move toward operational excellence. As digital transformation accelerates and industries demand greater efficiency, traceability, and automation, platform scales will continue to play a vital role in supporting competitive, data-driven operations. Choose wisely, and your investment will deliver measurable returns for years to come.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services