Also referred to as benchtop scales, these devices are so named because they are most often mounted to a counter, bench, table or other work surface. Read More…

Our industrial scales will astound you with their high performance, and longevity! For over six decades we have been providing our customers with exceptional service and products in order to better serve a global market. Our products serve in many different markets including aerospace, automotive and marine as well as many others. Get in touch with us today to learn more about what we can do for...

Load Cell Central is a leading manufacturer of load cells and industrial weighing equipment. We specialize in standard and custom load cells and digital indicators, floor scales and platform scales. Choose from thousands of types and models. We offer load cell repair to help in the reduction of costs.

As a scale manufacturer, OHAUS is a worldwide leader in the production of industrial scales and balance scales. Our line of industrial scales includes electronic scales, bench scales and counting scales. Our mass measurement tools are helpful in the education of students for concepts in math & science. Contact us soon and we will deliver to you reliable results.

Mettler-Toledo’s industrial weighing solutions include accurate, robust WIM systems for high-volume, in-motion vehicle weighing. These systems offer proven reliability & ease of use for vehicle weight enforcement applications – more efficient & cost-effective than static axle or full-platform scales. Our broad range of industrial, food, retail, & lab scales & analytics serves so many...

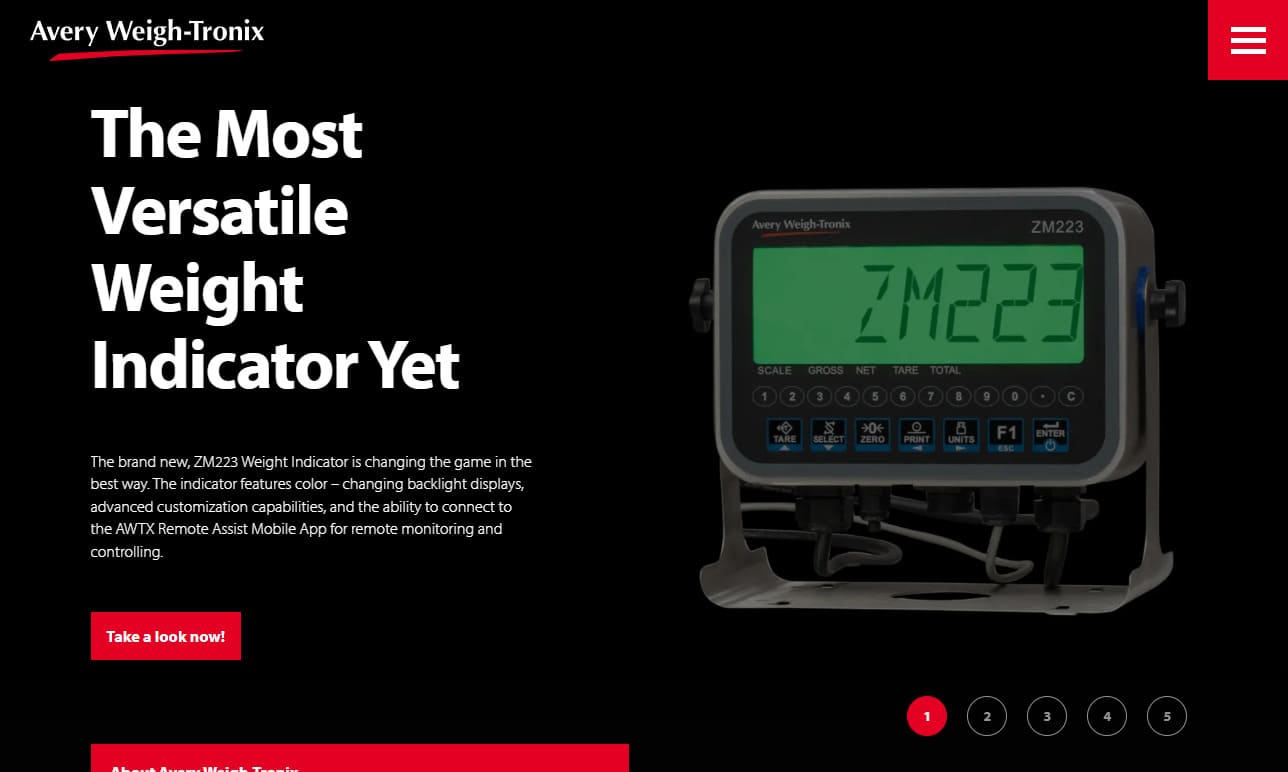

Avery Weigh-Tronix, one of the world’s largest suppliers of weighing solutions, has developed equipment for the full spectrum of industrial scale uses such as counting scales, bench scales, check-weighing scales, baggage scales, cargo scales, lift truck scales and many more. Innovative global weighing solutions – that’s what Avery Weigh-Tronix is all about! ISO 9001 Certified.

If you seek a digital scale, you are looking at the right company. Our selection from many name-brand scale manufacturers includes bench and floor scales; counting scales; electronic scales; freight and shipping scales; grain scales; hanging scales; industrial scales; pallet scales; postal scales. We have digital scales for any weighing application, and will match the price of any competitor for...

At Brecknell Scales, we are dedicated to delivering weighing solutions that combine accuracy, reliability, and ease of use. Our scales are designed to serve a wide range of industries, from manufacturing and logistics to food service and healthcare, ensuring that our customers can rely on precise measurements in their daily operations.

Cardinal/DETECTO is an ISO 9001:2008 registered company who designs, manufactures and markets weighing systems, load cells, weight indicators, remote displays, vehicle weight recording systems, and scales for all industries, including truck scales, weigh-in-motion highway scales, railroad scales, tank/hopper scales, livestock scales, bench scales, floor scales, counting scales, medical scales,...

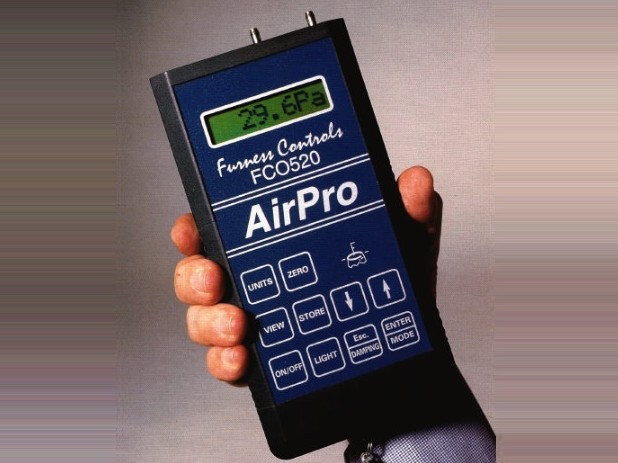

As a leading scale manufacturer, Setra Systems also designs and produces pressure and acceleration sensing equipment. Some industrial scale products include counting scales and laboratory balance scales. We also offer additional accessories like draftshields and dustcovers.

More Bench Scale Manufacturers

Industrial scales such as bench scales are commonly used in food, chemical, shipping and receiving, medical, pharmaceutical and retail industries as well as several other applications where small or medium sized goods are sold on the basis of weight. In some instances bench scales may also be used as counting scales, which work in reverse to determine the number of items from the weight rather than mass. To accommodate the many applications for which they are used, bench scales are available in a number of sizes, materials and with variable capacity and accuracy ratings.

Sizes vary from those scales covering only a few inches to those taking up the entirety of the surface to which they are mounted. Capacities likewise vary with some scales measuring items that weigh up to 2,000 pounds and others handling only small scale items weighing less than 150 grams. No matter the specific load rating, durable materials such as stainless steel, steel, aluminum, cast iron, ABS and brass are used to increase product longevity. Stainless steel and aluminum in particular are more often used in industries where sanitation is essential as they are hygienic materials capable of enduring repeated washings.

In addition to the aforementioned specifications, it is also crucial to consider the mechanism responsible for calculating the weight of a product, object or substance placed on the scale plate. The majority of bench scales fall into one of four categories: balance, spring, hydraulic or electronic. Balance scales consist of a bar resting on a central pivot point with identical platforms situated at either end. The object in question is placed on one plate, causing a shift in the balance of the bar.

Objects of confirmed and known weight are placed on the opposite platform until equilibrium is reached, at which point the two platters bear equal weight. Though common in laboratory settings, bench scales of this nature are rarely used in manufacturing. Instead, spring weighing scales are used in many applications. Springs located below the plate holding the load are calibrated with known and consistent resistance. The change in degree of compression due to the overhead force corresponds to particular weights. Hydraulics function in a similar manner, using the known displacement of fluids under pressure rather than springs.

Both mechanisms may also be used in conjunction with other measurement devices acting as shock absorbers. Finally, electronic scales, popular for ease of use and accuracy, use load cells and strain gauges located beneath the platform to determine the weight of a load. The degree of deformation encountered by a conductive coil or foil alters its electrical resistance. This change is then converted into an electronic signal, which supplies the data for the digital read out. The specific application for a given bench scale should be carefully considered when selecting a weighing mechanism.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services