Virtually all types of scales are available in an electronic configuration. Read More…

Our industrial scales will astound you with their high performance, and longevity! For over six decades we have been providing our customers with exceptional service and products in order to better serve a global market. Our products serve in many different markets including aerospace, automotive and marine as well as many others. Get in touch with us today to learn more about what we can do for...

Load Cell Central is a leading manufacturer of load cells and industrial weighing equipment. We specialize in standard and custom load cells and digital indicators, floor scales and platform scales. Choose from thousands of types and models. We offer load cell repair to help in the reduction of costs.

As a scale manufacturer, OHAUS is a worldwide leader in the production of industrial scales and balance scales. Our line of industrial scales includes electronic scales, bench scales and counting scales. Our mass measurement tools are helpful in the education of students for concepts in math & science. Contact us soon and we will deliver to you reliable results.

Mettler-Toledo’s industrial weighing solutions include accurate, robust WIM systems for high-volume, in-motion vehicle weighing. These systems offer proven reliability & ease of use for vehicle weight enforcement applications – more efficient & cost-effective than static axle or full-platform scales. Our broad range of industrial, food, retail, & lab scales & analytics serves so many...

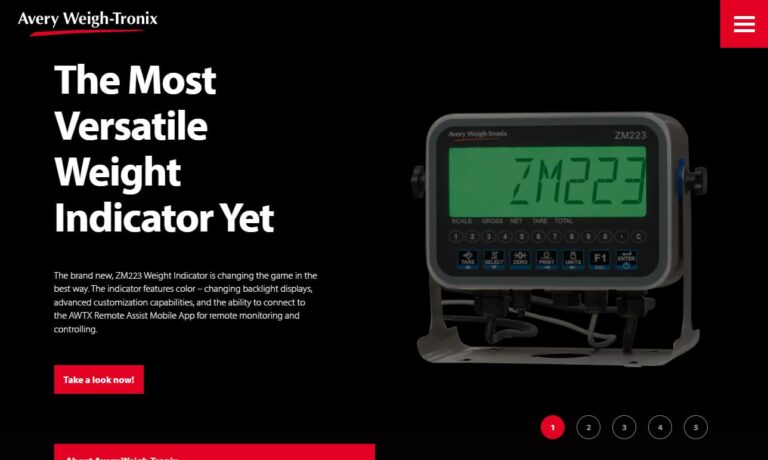

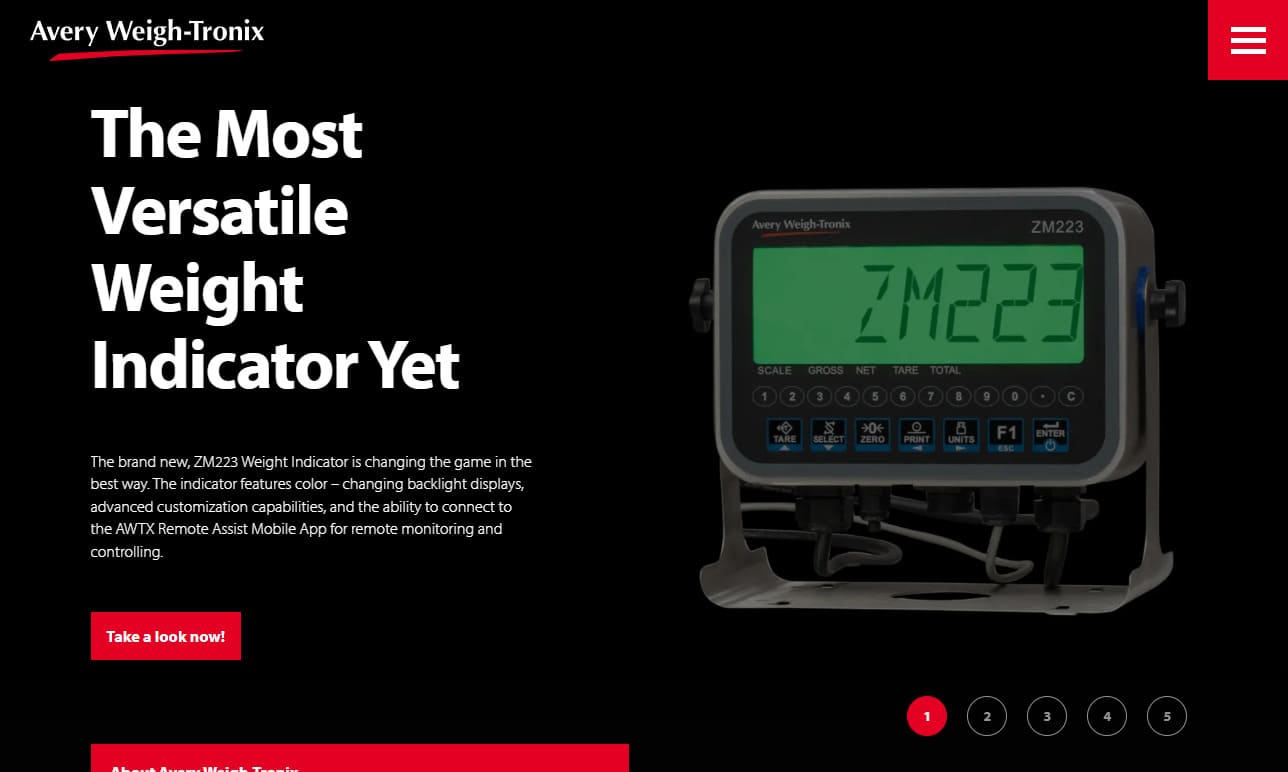

Avery Weigh-Tronix, one of the world’s largest suppliers of weighing solutions, has developed equipment for the full spectrum of industrial scale uses such as counting scales, bench scales, check-weighing scales, baggage scales, cargo scales, lift truck scales and many more. Innovative global weighing solutions – that’s what Avery Weigh-Tronix is all about! ISO 9001 Certified.

If you seek a digital scale, you are looking at the right company. Our selection from many name-brand scale manufacturers includes bench and floor scales; counting scales; electronic scales; freight and shipping scales; grain scales; hanging scales; industrial scales; pallet scales; postal scales. We have digital scales for any weighing application, and will match the price of any competitor for...

At Brecknell Scales, we are dedicated to delivering weighing solutions that combine accuracy, reliability, and ease of use. Our scales are designed to serve a wide range of industries, from manufacturing and logistics to food service and healthcare, ensuring that our customers can rely on precise measurements in their daily operations.

Cardinal/DETECTO is an ISO 9001:2008 registered company who designs, manufactures and markets weighing systems, load cells, weight indicators, remote displays, vehicle weight recording systems, and scales for all industries, including truck scales, weigh-in-motion highway scales, railroad scales, tank/hopper scales, livestock scales, bench scales, floor scales, counting scales, medical scales,...

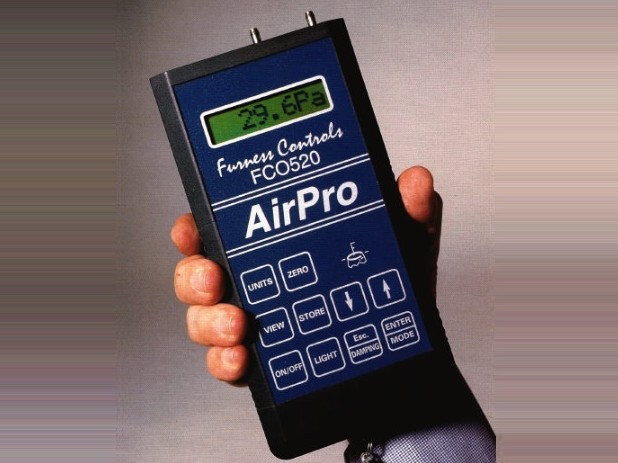

As a leading scale manufacturer, Setra Systems also designs and produces pressure and acceleration sensing equipment. Some industrial scale products include counting scales and laboratory balance scales. We also offer additional accessories like draftshields and dustcovers.

More Electronic Scale Manufacturers

There are many kinds of electronic scales. Platform scales such as bench scales and floor scales are most often electronic as are medical scales, truck scales and counting scales. While these may also employ alternative weighing systems such as springs, hydraulics and balance, electronic mechanisms are known to provide superior accuracy and precision as well as quick and easy results. For this reason they are preferred in research, science, medical and laboratory-based industries where scales must provide accurate measurements with precisions down to a fraction of a gram.

Far from limited, electronic scales are also pervasive in shipping and receiving, marine, postal, packaging, parts counting, building, construction, fishing, metal handling, aviation, food processing, batching, foundry, agriculture and nearly every other industry that requires the measurement of mass. With such a large variety of uses, several factors must be considered when selecting the proper industrial scale. The rate load, or maximum weight capacity, of a scale should be the primary concern as this should always exceed the weight of the largest load it will encounter. The dimensions of the scale must also accommodate anticipated loads.

The most common type of electronic scale employs a strain gauge system to calculate the total weight of a load. This apparatus is found beneath the plate or platform of the scale and works in the following manner. First, the girth of the load is evenly distributed with the use of springs or other shock absorbing apparatus. The force is then applied to one end of a load cell or an electrically charged double bending beam that then flexes downward where it deforms the strain gauge.

A strain gauge consists of conductive metal foil, tracking or coil that is bonded to a backing. As this backing encounters the weight, it too stretches or flexes. This deformation, created by the change in the electrical resistance of the load cells, is converted into an electrical signal that is directly proportionate to the weight on those cells. Finally, the signal runs through a digital converter that interprets or translates the data allowing the final calculation to be displayed on a digital LCD screen.

Larger, more complex systems or those in which the weight is not immediately needed often send the information to a computer interface with software to analyze and interpret the data. Electromagnetic force compensation and restoration electronic systems may also be responsible for measuring weight in electronic scales, though these are not used with as much frequency as the strain gauge model.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services