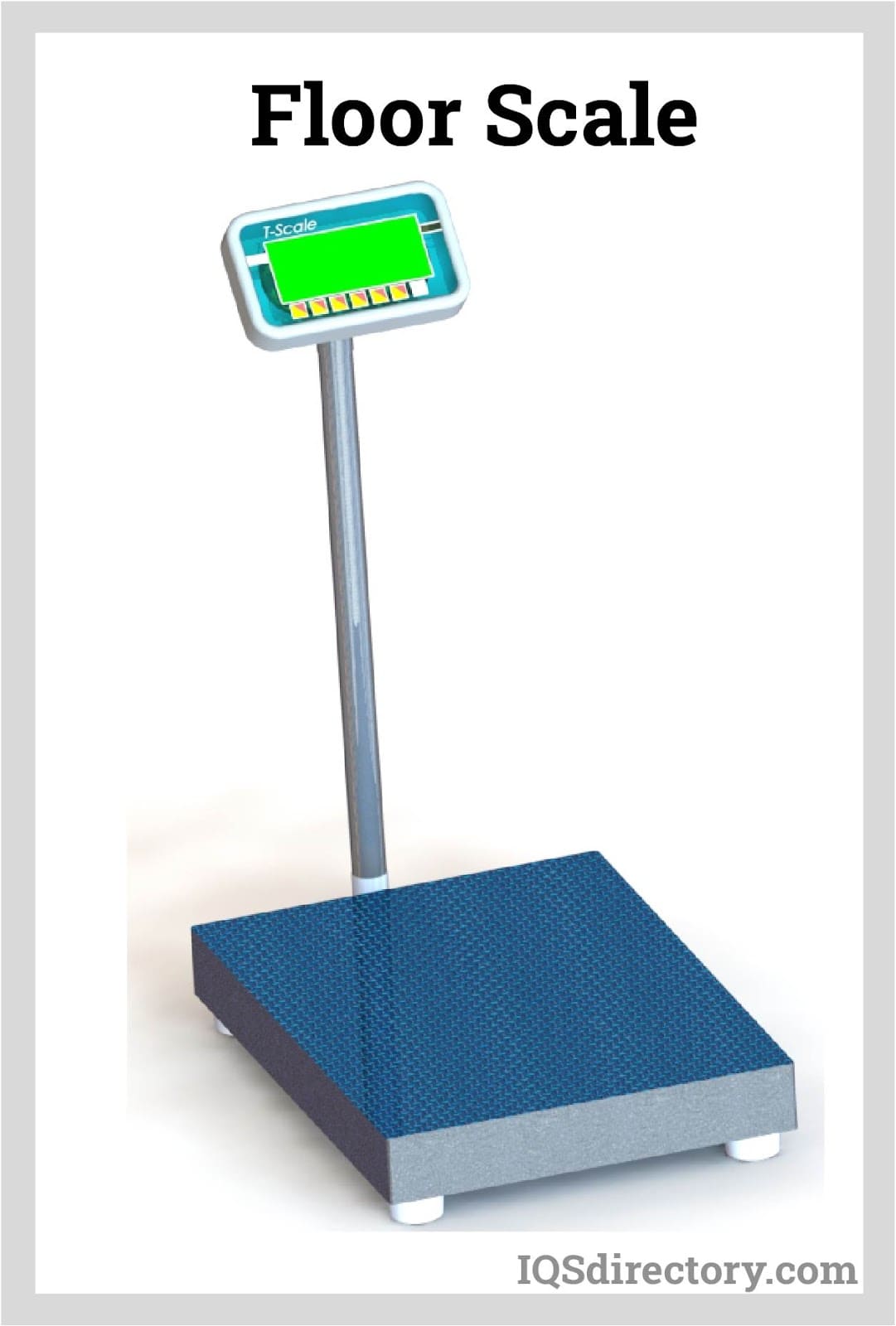

In various industrial, commercial, and consumer applications, items are weighed using floor scales and other ground-based weighing equipment. Floor scales are the best industrial weighing devices for measuring large loads, oversized objects, and other items that can be difficult to load onto a normal scale. Examples of these scales include platform scales, pallet scales, and pallet beams, which are all weighing devices operated at floor level. They are common in industrial settings and enterprises where smaller capacity sizes are insufficient. Read More…

Our industrial scales will astound you with their high performance, and longevity! For over six decades we have been providing our customers with exceptional service and products in order to better serve a global market. Our products serve in many different markets including aerospace, automotive and marine as well as many others. Get in touch with us today to learn more about what we can do for...

Load Cell Central is a leading manufacturer of load cells and industrial weighing equipment. We specialize in standard and custom load cells and digital indicators, floor scales and platform scales. Choose from thousands of types and models. We offer load cell repair to help in the reduction of costs.

As a scale manufacturer, OHAUS is a worldwide leader in the production of industrial scales and balance scales. Our line of industrial scales includes electronic scales, bench scales and counting scales. Our mass measurement tools are helpful in the education of students for concepts in math & science. Contact us soon and we will deliver to you reliable results.

Mettler-Toledo’s industrial weighing solutions include accurate, robust WIM systems for high-volume, in-motion vehicle weighing. These systems offer proven reliability & ease of use for vehicle weight enforcement applications – more efficient & cost-effective than static axle or full-platform scales. Our broad range of industrial, food, retail, & lab scales & analytics serves so many...

Avery Weigh-Tronix, one of the world’s largest suppliers of weighing solutions, has developed equipment for the full spectrum of industrial scale uses such as counting scales, bench scales, check-weighing scales, baggage scales, cargo scales, lift truck scales and many more. Innovative global weighing solutions – that’s what Avery Weigh-Tronix is all about! ISO 9001 Certified.

If you seek a digital scale, you are looking at the right company. Our selection from many name-brand scale manufacturers includes bench and floor scales; counting scales; electronic scales; freight and shipping scales; grain scales; hanging scales; industrial scales; pallet scales; postal scales. We have digital scales for any weighing application, and will match the price of any competitor for...

At Brecknell Scales, we are dedicated to delivering weighing solutions that combine accuracy, reliability, and ease of use. Our scales are designed to serve a wide range of industries, from manufacturing and logistics to food service and healthcare, ensuring that our customers can rely on precise measurements in their daily operations.

Cardinal/DETECTO is an ISO 9001:2008 registered company who designs, manufactures and markets weighing systems, load cells, weight indicators, remote displays, vehicle weight recording systems, and scales for all industries, including truck scales, weigh-in-motion highway scales, railroad scales, tank/hopper scales, livestock scales, bench scales, floor scales, counting scales, medical scales,...

As a leading scale manufacturer, Setra Systems also designs and produces pressure and acceleration sensing equipment. Some industrial scale products include counting scales and laboratory balance scales. We also offer additional accessories like draftshields and dustcovers.

More Floor Scale Manufacturers

Floor scales are essential industrial weighing devices designed to measure heavy loads and bulk materials with accuracy and efficiency. The sizes of floor scales vary greatly, with some platforms covering just a few square feet and others spanning several hundred. This significant range demonstrates the wide variety of applications for floor scales in daily operations across numerous sectors, from manufacturing and warehousing to logistics and agriculture. However, it is crucial to note that scale readings may be off if the scale is set up on soft surfaces such as carpets or floor mats. For the most accurate weight readings, a floor or platform scale should always be placed on a sturdy, level, and stable surface.

Choosing the right floor scale for your business’s needs requires an understanding of the different types available, their industrial applications, the benefits they offer, and the factors that influence your purchase decision. This comprehensive guide explores the main types of floor scales, their uses in various industries, and the key considerations for selecting the best floor scale for your operations. Whether you’re looking for a high-capacity industrial floor scale, a portable weighing platform, or a custom solution for a specific application, understanding the landscape of floor scale technology can empower you to make an informed investment that optimizes workflow, accuracy, and regulatory compliance.

Types of Floor Scales: Which Floor Scale Is Best for Your Application?

The ideal floor scale depends on the dimensions and weight of the items you need to weigh, the type of loading (manual or mechanized), your mobility requirements, and the available ramp space. Below are the primary varieties of floor scales, each tailored to specific industrial needs. Understanding these types can help you determine which industrial weighing solution is best suited for your facility’s unique requirements, helping you to streamline material handling, inventory management, and quality control.

Simple Floor Scales

Basic floor scales are the most common and versatile type of industrial weighing platform. These scales feature a rectangular or square flat platform, usually installed directly on the floor, and can accommodate a wide range of items from small packages to large pallets. The platform’s top may slope upward from the base, allowing for easier loading. Items can be loaded onto the scale manually or using moving tools such as pallet jacks, forklifts, pushcarts, or hand trucks. Typically constructed with a tread plate for slip resistance, these scales are also available in stainless steel for environments requiring extra hygiene or corrosion resistance, such as food processing facilities or chemical plants. Ramps can be added to these scales for efficient loading and unloading, making them an excellent choice for shipping departments, production lines, and warehouses.

Simple floor scales are often equipped with digital indicators for easy reading, and many models provide connectivity options for integration with warehouse management systems (WMS) or enterprise resource planning (ERP) platforms. This makes basic floor scales an entry point for businesses looking to automate their weighing procedures and data collection, supporting traceability and consistent quality assurance.

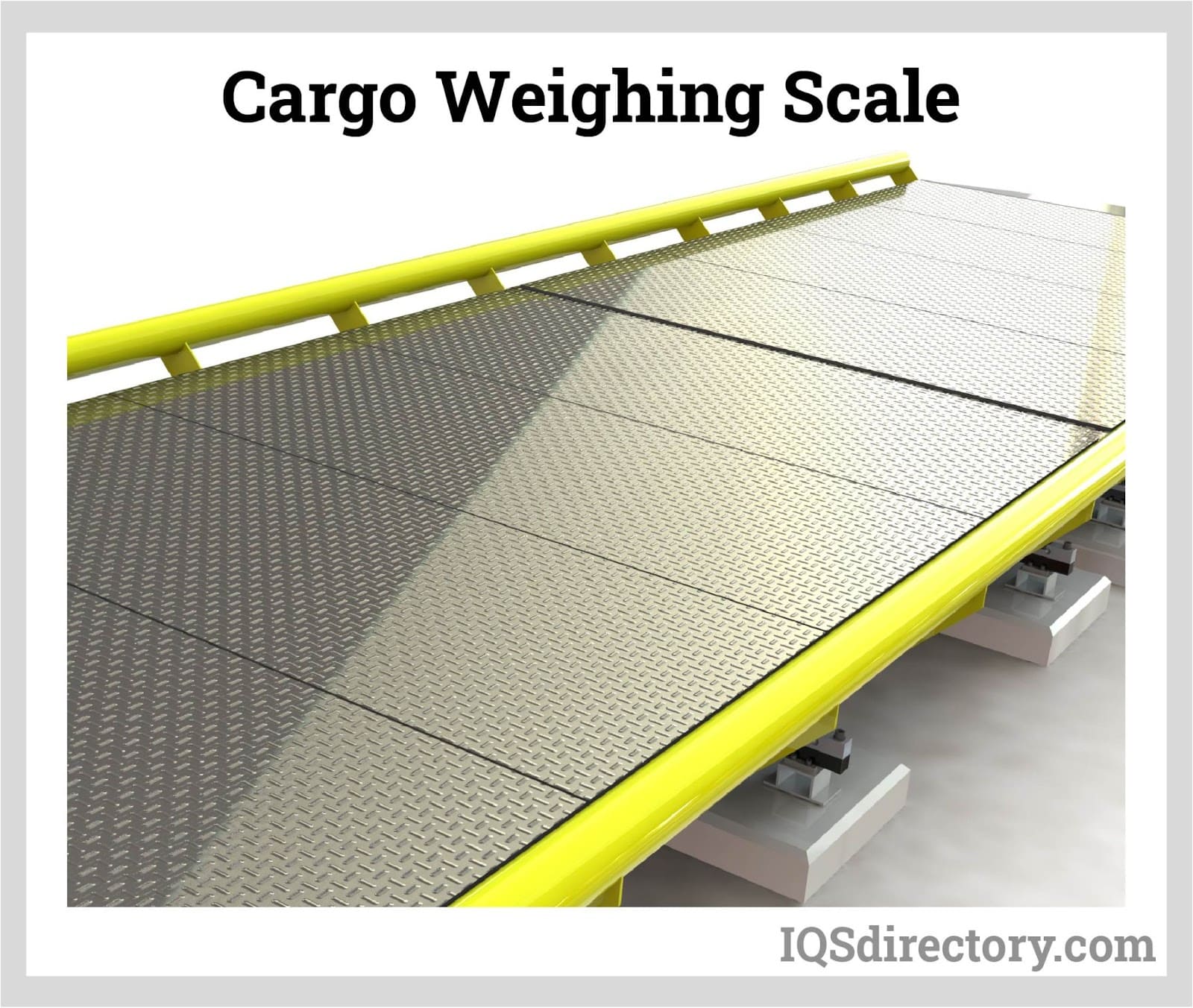

Cargo Scales

Cargo scales are engineered to handle the weighing of large, bulky shipments—particularly air cargo—in the freight and logistics sector. However, a variety of businesses can utilize these heavy-duty scales for weighing crates, pallets, and other oversized loads. Cargo scales often come in several designs, including roller cargo scales (featuring integrated rollers for smooth movement of heavy items) and models with swivel casters, which allow the scale to move easily in any direction. Some cargo scales are equipped with over a hundred heavy-duty casters, supporting high mobility and flexibility. These scales are typically larger and lower to the ground than standard floor scales, making them ideal for weighing large loads quickly and efficiently in distribution centers, shipping terminals, and air freight hubs.

When selecting cargo weighing scales, it’s important to assess not only the maximum load capacity but also the scale’s platform dimensions, ramp design, and compatibility with loading equipment. Customization options—such as integrated ticket printers, network interfaces, and automated tare functions—can further optimize throughput and accuracy in high-volume logistics operations. Cargo scales are vital for businesses that need to ensure compliance with transportation regulations and prevent overloading, which can result in costly fines and safety risks.

Truck Scales

Truck scales are large, robust weighing systems designed to measure the weight of loaded vehicles such as trucks, lorries, and trailers. These scales are critical for weighing cargo carried by trucks, monitoring overloaded vehicles on roads and bridges, and managing the flow of goods entering or leaving industrial facilities, warehouses, and ports. Many truck scales are essentially large-scale versions of floor scales, equipped with high-capacity platforms capable of supporting tens of thousands of pounds. They are commonly found at inspection and check stations along highways and at shipping/receiving docks. To ensure precise weight measurements, truck scales utilize multiple high-precision load cells (typically 6 to 12 per scale) that detect force at various points across the platform. Truck scales are indispensable in logistics, mining, construction, agriculture, and waste management, helping to maximize vehicle safety, optimize load distribution, and ensure regulatory compliance.

Modern truck scales can be pit-mounted or above-ground, with advanced features such as vehicle recognition systems, RFID integration, and digital data logging. These features not only improve the accuracy and speed of weighing but also support automated record-keeping and regulatory reporting. In industries where gross vehicle weight (GVW) and axle load compliance are critical, investing in a reliable truck scale is vital for operational safety and legal adherence.

Mobile/Portable Floor Scales

Portable floor scales are engineered for mobility, enabling users to transport the scale to different locations as needed. This flexibility makes portable weighing scales especially valuable in operations that require frequent relocation or temporary installations—such as fieldwork, remote warehouses, or multi-station production lines. Most portable floor scales are battery-powered, often featuring rechargeable batteries, so they can operate independently of a fixed electrical outlet. These mobile scales are typically fitted with durable caster wheels or rubber wheels at the base, allowing users to move the scale with ease. Ramps can be added for even greater convenience and accessibility. Portable floor scales offer a cost-effective alternative to installing multiple stationary scales, making them ideal for agriculture, shipping and receiving, and mobile clinics.

For buyers considering portable industrial floor scales, key considerations include battery life, ease of calibration, display visibility, and ruggedness for both indoor and outdoor use. Some portable scales can be folded or disassembled for compact transportation. In industries where weighing needs change rapidly or space constraints are a concern, mobile scales provide unmatched convenience and adaptability.

Low-Profile Scales

Low-profile floor scales address ramp space limitations commonly encountered in tight or crowded workspaces. Thanks to their unique design—where two sides are slightly elevated to accommodate load cells, but the rest of the platform is only about 2 inches high—these scales require much shorter ramps (often just 1 foot long). Some models have ramps as short as 6 inches. The low height allows for easier manual loading and unloading, as well as improved accessibility for pallet jacks and other moving equipment. Low-profile scales are frequently used in manufacturing, assembly, and packaging areas where space is at a premium but precise and fast weighing is necessary.

Low-profile industrial scales often offer features such as overload protection, anti-slip surfaces, and easy-clean designs, making them suitable for food production, pharmaceutical processing, and cleanroom environments. Their compact footprint, combined with high-precision load cells and digital indicators, ensures they deliver both accuracy and convenience in space-constrained settings.

Specialty and Custom Floor Scales

For unique industrial environments, specialty floor scales and custom-built weighing solutions are available. These include explosion-proof floor scales for hazardous areas, washdown scales for food processing and pharmaceutical industries (featuring sealed load cells and stainless steel construction for easy cleaning), and scales with integrated digital displays, printers, or network connectivity for advanced data management. Custom floor scales can be tailored for specific dimensions, weight capacities, or unique operational requirements, such as weighing drums, tanks, or livestock.

Specialty scales may also include checkweighers for fast-paced production lines, livestock scales with anti-slip and containment features, and heavy-duty platform scales designed for corrosive or wet environments. For buyers with highly specific needs, manufacturers can engineer custom industrial weighing solutions that align with regulatory, safety, and operational goals, ensuring long-term value and compliance.

Applications of Floor Scales: Where Are Floor Scales Used?

Floor scales are indispensable tools in modern industrial, commercial, and agricultural environments. Their versatility, durability, and precision make them suitable for a wide range of applications. When evaluating how to use an industrial floor scale, consider these common use cases that demonstrate the adaptability and importance of accurate weighing technology:

- Retail and Inventory Management: In the retail industry, floor scales streamline stock pallet loading and weighing, enabling quick and accurate results that minimize operational disruptions. They are also used for inventory control, order fulfillment, and shipping/receiving processes. Floor scales play a key role in preventing inventory discrepancies and supporting just-in-time (JIT) inventory strategies.

- Warehousing and Storage: In warehouses and storage facilities, floor scales are utilized for statistical record-keeping and to verify the weight of goods in storage or transit. This supports logistics planning, loss prevention, and compliance with shipping regulations. Large-capacity floor scales help optimize warehouse management and reduce shipping errors.

- Agriculture: Portable floor scales are frequently used to weigh bulk agricultural products such as grain, fertilizer, lumber, bamboo, hemp, flax, and silk. Ranchers and livestock operators use specialized livestock floor scales to monitor the weight and growth of cattle, pigs, sheep, and other animals, ensuring accurate feed management and health tracking. In addition, floor scales are used for weighing seed, fertilizer, and harvested crops to ensure precise record-keeping and optimize crop yield management.

- Healthcare and Medical Applications: In the healthcare industry, various types of floor scales are used for patient care—including digital floor scales for weighing adults or children, bariatric scales for heavier patients, and neonatal scales as part of treatment plans to track a baby's growth. These scales are also utilized in veterinary clinics for weighing animals. Precise weighing is critical for dosing medication, tracking patient progress, and meeting regulatory requirements in medical facilities.

- Manufacturing and Production: Floor scales are employed on the production floor to weigh raw materials, finished goods, and waste, supporting quality assurance, process control, and inventory management in factories producing everything from food and beverages to chemicals and electronics. Accurate weighing at every stage helps reduce waste, maintain product consistency, and ensure compliance with quality standards such as ISO or HACCP.

- Construction and Mining: Heavy-duty floor scales and truck scales are essential for weighing construction materials (such as aggregates, cement, and steel beams) and for tracking vehicle payloads in mining operations, ensuring compliance with legal weight limits and optimizing resource allocation. In mining, high-capacity platform scales help monitor ore output and prevent equipment overloads, improving site safety and equipment longevity.

- Waste Management and Recycling: Floor and platform scales are used for weighing recyclable materials, refuse, and hazardous waste, supporting accurate billing, regulatory compliance, and sustainable waste management practices. Waste handlers rely on industrial scales to ensure fair billing and to track recycling rates, supporting environmental stewardship initiatives.

- Logistics and Freight: In shipping terminals, distribution centers, and freight companies, floor scales provide fast and reliable measurements of cargo, improving load planning, shipment accuracy, and overall efficiency. Automated weighing and data capture increase productivity and reduce the risk of costly shipping errors or compliance violations.

Beyond these industries, floor scales are also used in laboratories, food service, packaging, and energy production, wherever precise and reliable weight measurement is essential to business operations and compliance.

Benefits of Floor Scales: Why Invest in Industrial Floor Scales?

Floor scales are a smart investment for any business that requires accurate, efficient, and reliable weighing solutions. Here are some of the top advantages of choosing the right industrial floor scale for your facility. If you’re considering a purchase, understanding these benefits can help you align your investment with your productivity, safety, and compliance objectives:

- High Load Capacity: Floor scales are designed to bear heavier loads than most standard weighing devices, making them ideal for industrial, commercial, and heavy-duty applications. Whether you need to weigh a single pallet or a fully loaded truck, selecting a scale with the appropriate maximum capacity ensures long-term performance and safety.

- Durability and Longevity: Constructed with robust materials such as steel or stainless steel, floor scales are built to withstand frequent use, harsh environments, and demanding workloads. Many models offer weatherproof or corrosion-resistant finishes for added longevity. This is especially critical in industries exposed to moisture, chemicals, or outdoor conditions.

- Versatility: Available in various sizes, capacities, and configurations, floor scales can handle a wide range of weighing needs—from small packages to large pallets and vehicles. Specialty attachments and features (like ramps, printers, or wireless displays) further enhance their versatility. This adaptability makes floor scales a core component in multi-use facilities and dynamic work environments.

- Portability (for Mobile Models): Portable floor scales are easy to move, store, and deploy as needed, reducing equipment costs and increasing operational flexibility in dynamic or remote environments. Battery-powered models with wireless data transmission enable weighing operations in locations without permanent infrastructure.

- Time Savings: Floor scales simplify the process of weighing large or bulky items, allowing workers to weigh freight without unloading trucks or to process bulk purchases by weight quickly and efficiently. Automation features such as programmable tare, digital displays, and barcode scanning further reduce handling time and human error.

- Improved Accuracy and Compliance: Modern floor scales utilize advanced digital load cells and electronics to deliver precise measurements, supporting compliance with trade, shipping, and safety regulations. Regular calibration and certification help ensure measurement accuracy meets industry standards, including NTEP and OIML requirements.

- Enhanced Safety: By reducing manual lifting and streamlining material handling, floor scales help to minimize workplace injuries and improve overall safety for employees. Anti-slip surfaces, low-profile ramps, and overload protection features further reduce risk in busy environments.

- Integration with Data Systems: Many industrial floor scales can be integrated with inventory management, ERP, or shipping software, providing seamless data capture and reporting for enhanced business intelligence. Digital connectivity supports traceability, audit trails, and real-time analytics, empowering data-driven decision-making.

Additional benefits include reduced product giveaway, improved customer satisfaction due to accurate shipments, and easier compliance with industry regulations and customer requirements. The right floor scale can be a key asset in your continuous improvement and operational excellence initiatives.

Key Decision Factors: How to Choose the Right Floor Scale for Your Business

When selecting a floor scale, consider the following decision factors to ensure you choose the right solution for your operational needs. The purchase of an industrial floor scale or platform scale is a significant investment—factoring in these criteria will help you maximize return on investment and streamline day-to-day weighing processes:

- Capacity and Accuracy: Determine the maximum weight you need to measure and the degree of precision required for your applications. Choose a scale with an appropriate capacity and accuracy rating for your industry—whether you need to weigh light packages or heavy vehicles. Consider both the minimum readable increment (resolution) and the total weighing range.

- Platform Size and Material: Select a platform size that accommodates your largest loads and fits your available space. Consider stainless steel or washdown options for environments requiring frequent cleaning or exposure to moisture and chemicals. The platform surface should be slip-resistant and easy to clean for maximum safety and hygiene.

- Scale Type: Decide between stationary, portable, or low-profile models based on your workspace layout, mobility needs, and frequency of use. Think about whether you need flexibility for multiple locations or a dedicated, permanent installation.

- Environment: Assess environmental factors such as temperature extremes, humidity, dust, and potential exposure to corrosive substances. Opt for weatherproof or sealed models in harsh conditions. For hazardous areas, explosion-proof floor scales may be required for safety and compliance.

- Ramp and Accessibility: Consider ramp size, slope, and accessibility for loading/unloading by hand or with equipment such as forklifts or pallet jacks. Shorter ramps and low-profile platforms improve ergonomics and workflow in space-limited areas.

- Digital Features: Evaluate the importance of features such as digital readouts, wireless connectivity, data logging, barcode scanners, or integration with your business software. Connectivity options can include Ethernet, Bluetooth, USB, or Wi-Fi, depending on your IT infrastructure and data management needs.

- Maintenance and Calibration: Look for scales with easy-access load cells, removable platforms, or self-diagnostic features that facilitate ongoing maintenance and calibration. Some advanced models offer predictive maintenance alerts, reducing downtime and extending service life.

- Industry Certifications: For legal-for-trade applications, ensure the scale is NTEP-certified or meets relevant regulatory standards for your industry. Certification supports trust with customers and regulatory agencies, especially in commercial transactions.

- Total Cost of Ownership: Consider not only the initial purchase price but also ongoing costs for calibration, repairs, parts, and potential software upgrades. Reliable brands with strong support networks can reduce long-term maintenance expenses.

- Warranty and Support: Assess manufacturer warranties, service agreements, and technical support options, especially if your operations are mission-critical or located in remote areas.

By systematically evaluating these criteria, you can confidently select a floor scale or industrial weighing system that aligns with your operational requirements, regulatory obligations, and budget constraints.

Frequently Asked Questions About Floor Scales

What industries use industrial floor scales most often?

Industrial floor scales are widely used in manufacturing, warehousing, logistics, agriculture, construction, mining, healthcare, food processing, recycling, and waste management. Their adaptability and robustness make them essential tools in any operation that requires weighing heavy or bulky items. Many businesses also deploy floor scales in retail distribution, laboratory research, and packaging environments where consistent and accurate weight measurements are critical for quality and compliance.

What is the difference between a floor scale and a platform scale?

The terms "floor scale" and "platform scale" are often used interchangeably, but a floor scale specifically refers to a weighing system designed to be installed directly on the floor for weighing large or heavy items, while a platform scale can refer to any weighing device with a flat surface, including bench scales or tabletop models. Floor scales typically offer higher capacities and larger weighing platforms. Platform scales may be used for lighter loads or as part of conveyor systems, whereas floor scales are optimized for heavy-duty, high-capacity industrial weighing applications.

How do I maintain and calibrate my floor scale?

Regular cleaning, inspection, and calibration are essential for accurate and reliable operation. Keep the platform free of debris, check load cells and cables for damage, and calibrate the scale as recommended by the manufacturer. For legal-for-trade applications, periodic certification by a qualified technician may be required. Many industrial floor scales include diagnostics or alerts to remind users when calibration is due, helping to maintain compliance with industry standards and extend the lifespan of the equipment.

Can floor scales be integrated with inventory or shipping software?

Yes, many modern floor scales offer connectivity options such as USB, Ethernet, or wireless interfaces, allowing seamless integration with inventory management, ERP, or shipping software to automate data collection and improve workflow efficiency. This integration is particularly valuable for businesses that require real-time data transfer, automated reporting, or remote monitoring capabilities. Selecting compatible hardware and software during the buying process ensures future scalability and improved operational efficiency.

What are key features to look for when buying a floor scale?

Key features include load capacity, platform size, accuracy, digital display readability, data connectivity, rugged construction, ease of maintenance, and any specialty requirements (such as washdown capability or explosion-proof design). Buyers should also consider user interface simplicity, programmable functions, battery life (for portable models), and the availability of support and spare parts from the manufacturer.

How can I ensure my floor scale remains accurate over time?

To maintain consistent accuracy, schedule regular maintenance and calibration checks according to the manufacturer’s guidelines. Protect the scale from excessive shock or overload, ensure it is installed on a stable surface, and keep the platform clean and free of debris. Using certified test weights and employing qualified technicians for calibration helps maintain NTEP or OIML certification where required.

What software integrations are available for industrial floor scales?

Many industrial floor scales are compatible with software solutions for inventory control, shipping, asset tracking, and production data management. Integration can include barcode readers, label printers, and cloud-based data platforms, providing end-to-end traceability and real-time analytics to support lean manufacturing, supply chain optimization, and regulatory compliance.

Can I upgrade my existing floor scale with new features?

Many manufacturers offer upgrade kits or modular accessories, such as remote displays, wireless modules, or advanced data interfaces. When purchasing a new floor scale, consider future-proofing your investment by selecting models with expansion options, open communication protocols, and compatibility with your facility’s evolving needs.

Choosing the Correct Floor Scale Manufacturer

To make sure you have the most positive outcome when purchasing floor scales from floor scale manufacturers, it is important to compare at least four manufacturers using our list of floor scale companies. Each floor scale manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each floor scale company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple floor scale companies with the same form. By thoroughly vetting scale suppliers, comparing product specifications, warranty terms, and customer reviews, you can confidently choose a partner that will deliver reliable weighing solutions that meet your unique business requirements.

Summary: Maximize Operational Efficiency with the Right Floor Scale

Floor scales are indispensable in today’s fast-paced industrial environments, offering superior accuracy, reliability, and versatility for weighing everything from small parcels to loaded trucks. By understanding the types of floor scales available, their industry-specific applications, benefits, and the decision factors that matter most, you can select the perfect weighing solution for your business. Whether you require a heavy-duty industrial floor scale, a portable model for fieldwork, or a specialty scale for unique environments, investing in the right floor scale can streamline your operations, improve safety, and support your growth for years to come.

The right industrial floor scale not only enhances efficiency and compliance but also drives down operational costs, minimizes safety risks, and supports data-driven decision-making. With careful planning and consideration of your facility’s specific needs, your investment in a quality floor scale will deliver measurable returns in productivity, accuracy, and long-term value.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services